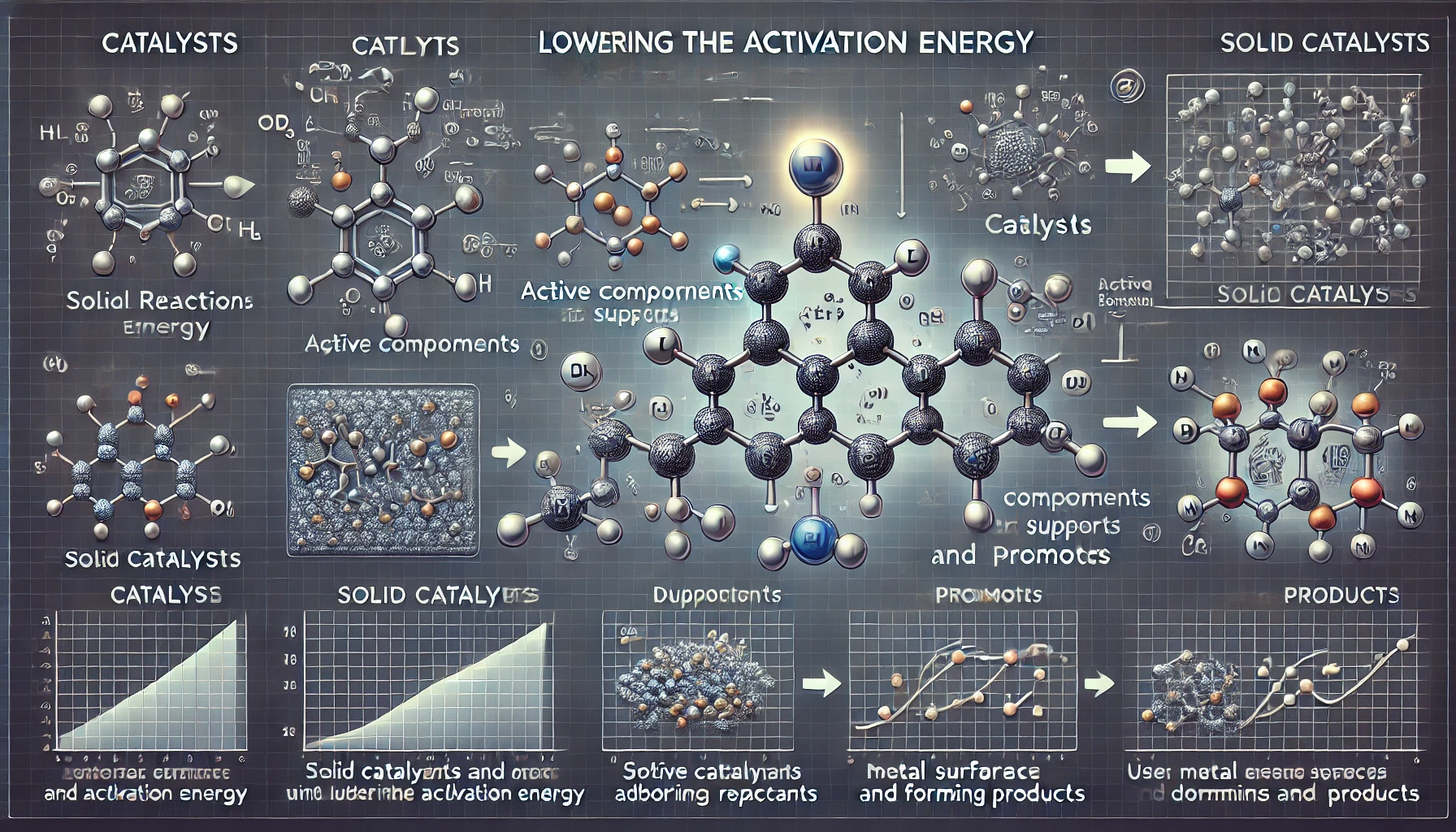

In chemical reactions, catalysts increase the rate of a reaction by lowering the activation energy, and solid catalysts are composed of an active ingredient, a support, and an enhancer to maximize efficiency. The active ingredient adsorbs reactants, the support provides thermal stability, and the enhancer modulates activity, making them essential in a variety of industries.

Activation energy and the role of catalysts

The minimum kinetic energy required for molecules to meet and undergo a chemical reaction is called activation energy. In a reaction with a small activation energy, the reaction proceeds rapidly because there are many molecules with kinetic energy greater than the activation energy of the reaction. For example, in a combustion reaction, a low activation energy allows the reaction to occur easily, releasing heat and light quickly. Conversely, if the activation energy is high, the reaction proceeds slowly and only occurs under certain conditions.

A substance that changes the rate of a reaction by controlling the activation energy is called a catalyst, and its ability to speed up a reaction is called catalytic activity. A catalyst provides a new reaction pathway with a different activation energy than the one in the absence of a catalyst. Catalysts increase the rate of a reaction by lowering the activation energy of the reaction, allowing more molecules to have enough energy. Because catalysts do not change themselves before or after a reaction, a small amount can have a large effect. Thanks to these properties, catalysts play an important role in many industries.

The importance and components of solid catalysts

The chemical industry mainly uses solid catalysts because they don’t require a separate process to separate the liquid or gaseous product from the catalyst. Solid catalysts are mostly composed of an active ingredient, a support, and an enhancer. The active component is the material that provides catalytic activity by adsorbing reactants onto its surface. In the catalysis of solid catalysts, the reactants are first chemisorbed on the surface of the active component, the adsorbed reactants react on the surface and are converted into products, and the products are desorbed from the surface to complete the reaction.

Metals are used as active ingredients in many reactions because a variety of substances can be adsorbed onto their surface. For example, iron is used as an active ingredient in the synthesis of ammonia, where the reactants hydrogen and nitrogen are adsorbed onto the surface of the iron and separated into their respective atomic states. The adsorbed reactants are stabilized by sharing electrons with atoms on the metal surface. The adsorption strength of the reactants depends on the type of metal. The adsorption strength must be appropriate. Weak adsorption results in low catalytic activity because the amount adsorbed is small, while too strong adsorption results in low catalytic activity because the adsorbed reactants are overly stabilized, slowing down the reaction on the surface. In general, in solid catalysts, the more active component atoms on the surface involved in the reaction, the more reactants are adsorbed, and the higher the catalytic activity.

Thermal stability of catalysts and the role of supports

Metals have low thermal stability, so at high temperatures where chemical reactions occur, small particles of metal atoms stick together to form larger particles, which is called sintering. When the particles are sintered, the total surface area of the metal active ingredient is reduced. The solution to this problem is a support. By dispersing small metal particles on the surface of a support with a large surface area and high thermal stability, the degradation of catalytic activity due to sintering is suppressed. Therefore, even small amounts of metal can increase the activity of solid catalysts that use metal as an active ingredient.

The role of enhancers in increasing the efficiency of catalysts

Enhancers are incorporated into catalysts in small amounts to modulate their activity. They can change the surface structure of the active ingredient to inhibit sintering, or they can change the electron density of the active ingredient to control the strength of adsorption. For example, adding a small amount of ruthenium to a platinum catalyst can increase the reaction efficiency. This is because ruthenium changes the electronic structure of platinum, optimizing the adsorption of reactants and the reaction rate. Solid catalysts must have an active component, but in some cases they do not contain enhancers or supports.

Practical applications of solid catalysts

Solid catalysts play an essential role in many different chemical processes. For example, metals such as platinum, palladium, and rhodium are used as catalysts in automotive emission control systems. These catalysts reduce environmental pollution by converting harmful exhaust gases into less harmful substances. Catalysts are also used in the petroleum refining process to convert crude oil into useful products such as gasoline and diesel. The efficiency of these catalysts is crucial for both economic and environmental reasons.

In conclusion, catalysts play an important role in increasing the reaction rate by regulating the activation energy of chemical reactions and are widely used in various fields, including the chemical industry. The proper combination of active ingredients, supports, and enhancers in solid catalysts maximizes the efficiency of the catalyst, which greatly contributes to the efficiency of modern industry and environmental protection.