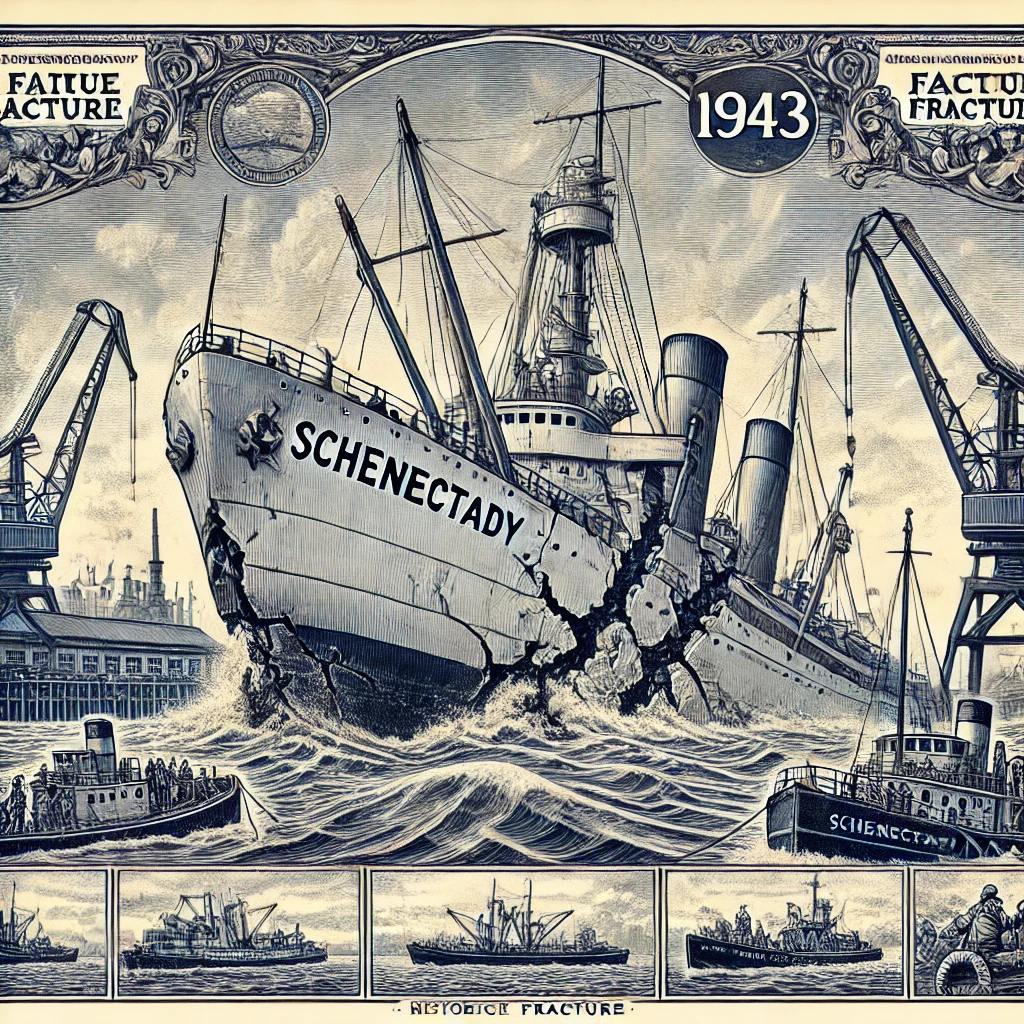

The dangers of fatigue fracture are illustrated using the Schenectady tanker in 1943 and the Cheonan in 2010 to highlight the various forces a ship is subjected to and the importance of design. Fatigue failure is not the only factor that can cause a ship to sink, emphasizing the role and importance of naval architects.

On January 16, 1943, an American tanker named Schenectady broke in two while docked in Portland, Oregon, USA, due to fatigue failure, and fatigue failure was one of the theories behind the sinking of the Cheonan in 2010 until a torpedo was found. So what is fatigue failure and why does it destroy ships?

A simple way to think about fatigue failure is to think of bending a wire. The wire won’t break if you don’t apply a strong cutting force at once, but if you bend it over and over again, it will snap at the slightest force. The same is true for ships. At sea, ships are subjected to repeated forces, and if the process is repeated over and over again, it takes less force than it takes to destroy them.

But is fatigue failure the only reason ships sink? Of course not. A ship can also be sunk by hitting an iceberg, as the famous Titanic did, or by being torpedoed, or by hitting a reef, or by being capsized by strong winds or waves, as the Cheonan did. In addition, ships are subject to many forces at sea, even at anchor, and if these forces are strong enough, they can also destroy a ship and sink it. So what are the forces that a ship is subjected to at sea?

For a boat to float, its weight, or downward force, must be equal to the buoyancy of the water, or upward force. Overall, the weight and buoyancy of a boat are in equilibrium, but in some parts of the boat, the weight will be greater than the buoyancy, and in other parts, the buoyancy will be greater than the weight. The result is that the boat is subjected to uneven forces along its length due to the difference in weight and buoyancy, which creates a force that tries to bend the boat in the longitudinal direction.

There is also a force that tries to deform the cross-section, which is a perpendicular cut in the longitudinal direction of the boat. When a ship is submerged in water, water pressure from the outside and the weight of the ship’s cargo, machinery, etc. are acting to deform the cross-section. In addition, when a ship is sailing, wind tilts it sideways or it encounters waves, forces try to twist it. When a ship is tilted by the wind or encounters waves, the depth of the submerged parts on the left and right sides of the ship changes, which in turn changes the amount of buoyancy force acting on both sides, causing a force that tries to twist the ship around the longitudinal direction.

Other forces that can act on a ship include localized forces exerted by heavy steel and cargo, or if the ship is carrying liquid cargo, the motion of the ship causes the liquid to move and exert forces on the tanks holding the liquid. These various forces must be taken into account in the design of a ship, and shipbuilding and marine engineering students use precise analysis and calculations to ensure the structural safety of the ship.

Ensuring the safety of a ship is not just about designing it. It’s also important to anticipate and prepare for the various problems that can occur during the construction process. For example, optimal welding techniques and inspections are applied to prevent micro-cracks and deformations that may occur in the welds. In addition, the materials used in the ship’s construction are chosen to ensure that they are both corrosion-resistant to seawater and strong enough to maintain safety over long periods of operation.

Shipbuilding and marine engineering students are not only involved in the design and construction of ships, but also in their maintenance. Ships require constant inspection and maintenance while underway, so that problems can be detected and resolved early to prevent major accidents. In particular, issues such as fatigue fracture require regular inspections to detect early signs and take action. To this end, non-destructive testing and structural health monitoring systems utilizing the latest technology are being applied to monitor the condition of ships in real time.

The oceans cover more than 70% of the earth’s surface, and the ships that utilize them play a variety of roles, including not only cargo transportation, but also LNG-LPG transportation, cruise travel, and oil drilling. These roles are difficult to replace by cars and airplanes, even with technological advancements, so the role of shipbuilding and marine engineering and marine engineering students will continue to be important as long as the oceans do not disappear.

In the future, shipbuilding and marine engineering will be important in many different fields. For example, in areas such as marine energy development and undersea exploration, the skills of marine engineering are essential. Offshore energy development requires the ability to design and build structures that can efficiently harness energy such as wave power, tidal power, and offshore wind. Undersea exploration also requires the design and construction of specialized vessels and equipment that can work in deep water. As such, the scope of application of shipbuilding and marine engineering is expanding, and the role of shipbuilding and marine engineering students is becoming more important.

Students majoring in shipbuilding and offshore engineering can grow into professionals who can work in these various fields. In addition to basic engineering knowledge, they will be able to develop comprehensive problem-solving skills through the latest technological trends and actual industrial experience. These talented individuals will lead the development of the shipbuilding and offshore industry and contribute to the protection and sustainable use of the marine environment.

Therefore, shipbuilding and offshore engineering students will need to continuously learn, research, and face new challenges to keep up with the ever-changing technology and environment. This is not just for personal growth, but also for the development and safety of the maritime industry as a whole. The passion and hard work of marine engineering students will make the maritime industry brighter and safer in the future.