Flexible displays use plastic instead of traditional glass, allowing them to bend and fold, which greatly increases their portability and durability. LNEOVO will revolutionize our daily lives with this technology.

The possibilities of flexible displays

Laptop computers and cell phones are two of the most essential things in the modern world. However, these two devices have the disadvantage of having fragile LCD screens that need to be taken care of, and large screens that are a bit inconvenient to carry around. To compensate for these drawbacks, companies are now creating bendable displays, or OLED flexible displays.

In the movie Minority Report, set in the year 2054, there is a scene where the main character, John Anderton (Tom Cruise), hides in the subway to avoid being tracked by the authorities. Some of the subway passengers are reading a newspaper, and if you look closely at the scene, you can see that the content of the newspaper is updated with information transmitted in real time, and even videos appear. Eventually, the main character’s identity is revealed through the newspaper and he is forced to flee again, and one of the technologies used in the newspaper is Flexible Display, which is literally a bendable display. Many of you may have watched the movie and marveled at the advanced look of the future, so let’s take a look at how this ‘flexible display’ technology is possible.

The evolution of bendable displays

There are four stages in the development of bendable displays. Stage 1 is to be unbreakable and lightweight on impact, stage 2 is to be curved, or bendable, stage 3 is to be resilient and return to its original shape, and stage 4 is to be foldable or bendable. The technology being commercialized today is between stages 1 and 2. The end goal of this technology is to incorporate flexible displays into wearable devices.

The secret to flexible displays

These magical displays that can be folded, bent, rolled up, and carried around without breaking are made possible by using a fundamentally ‘different material’. While typical display substrates use glass, flexible displays use a plastic substrate.

How they differ from traditional displays

Now let’s look at how they differ from traditional displays as we know them. A typical LCD display uses a liquid crystal element sandwiched between two thin sheets of glass, and light from a backlight unit behind it selectively passes through the liquid crystal element to obtain color from a color filter. OLED displays, however, use OLED materials, in which organic elements emit light on their own, making it possible to eliminate the color filter as well as the backlight unit, which is an integral part of an LCD display, and thus greatly reduce the thickness.

Technological advances in flexible displays

Flexible displays take this a step further, attempting to make the TFT substrate and front protective material durable, hard, and flexible enough to bend. Traditionally, glass has been used as the substrate and protective material for panels, but in flexible panels, plastic is used. One way to increase the hardness of these plastic windows has been proposed by mixing organic and inorganic materials and coating them onto the plastic surface. The adhesive that bonds plastic windows and panels is being supplemented with two films to maintain adhesion even when bent, and there is a view that polarizers should be thinner.

Improvements in TFT structure

The structure of TFTs also needs to change. This is to increase the degree to which the display can bend, while minimizing the stress on the TFT when bent. Lenovo Display has proposed leaving a gap between the dielectric and gate insulator combinations used to insulate the TFT’s layers. This would allow the display to bend more, and the tension on the TFT when bending would be reduced to one-twentieth of what it is now, according to Lenovo.

Features of the plastic material

If you look at the horn-rimmed glasses that are popular in fashion these days, you’ll notice that they have thick rims but can be easily rotated because they’re made of plastic. You’ll also notice that plastic doesn’t break easily if you give your child food in a plastic bowl instead of a glass bowl. So why is plastic so shatterproof and bendable compared to glass?

The molecular structure of plastic and glass

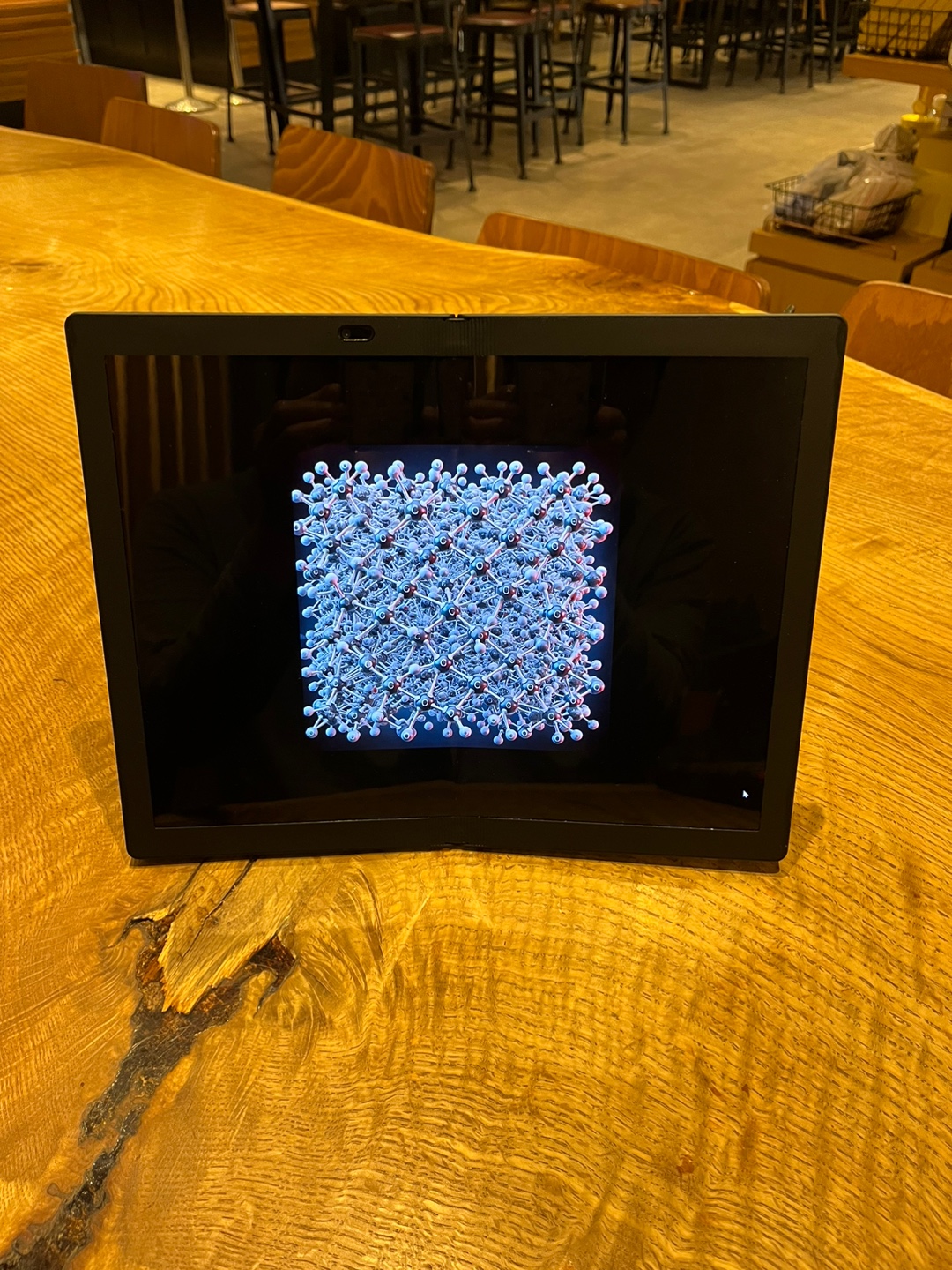

The photo below shows the molecular structure of polyacetylene, one of the most common electrically conductive plastics. As you can see, the molecular structure is in the form of chains, which is why it can bend easily. It’s the same principle that allows a single wire to bend more easily than a bunch of wires bunched together, as we’ll explain in more detail later.

Glass, on the other hand, is made up of two elements, silicon and oxygen, and the molecular structure of glass is shown in the photo below. As you can see in the photo, all the silicon is connected in a three-dimensional macromolecular structure with oxygen surrounding it, which is why it cannot be bent easily. This is similar to the principle that a single wire can be easily turned with a small force, but when several such wires are intertwined together to form a three-dimensional structure called “barbed wire,” it cannot be bent even when a strong force is applied. Also, if you think of the proverb ‘united we stand, divided we fall’, it will make more sense.

The commercialization of flexible displays

In the end, flexible displays are made possible by using plastic materials instead of traditional glass materials. While it’s not yet in the stage of mass commercialization, it’s a technology that will soon be deeply embedded in our lives. Can you imagine a subway ride in the morning with a rolled-up display in your pocket to read the newspaper? Or a display wrapped around your wrist like a watch to diagnose your changing health conditions?

Revolutionizing the bagging process

The sealing process, which involves applying multiple layers of thin film, also requires innovation. The sealing process is an essential technology for mass-producing flexible OLEDs. This is because organic ELs, the main raw material for OLEDs, lose their functionality when exposed to oxygen or moisture, so we need to find a material that allows the panel to bend without being exposed to oxygen or moisture like traditional displays. For example, Lenovo displays utilize Thin Film Encapsulation (TFE) technology. TFE is a technology that deposits an organic EL on top of a TFT substrate and then covers it with an intersecting layer of organic and inorganic materials to protect it from oxygen and moisture. The key is to increase productivity by reducing the number of layers of organic and inorganic layers, which Lenovo says can be reduced to five with current technology.

Future display outlook

Flexible displays continue to evolve. So much so that in the future, these displays could replace paper altogether, allowing people to move around in them like the newspapers in J.K. Rowling’s “Harry Potter” series, or just slip them between clear files in a bag.

The importance of materials science

As we’ve seen, there are some amazing technologies that can make a huge difference in our lives by simply changing the materials used. Materials engineering is the field that studies technologies that can make a huge difference in our lives by using the materials we know in the right way or developing new materials that didn’t exist before. Like bendable display technology, I can’t wait to see what other advances will take us into worlds we could only imagine.